|

Product Overview

|

Product Name: Plastic Injection Mold Making for Auto Wire Bushing

Production Introduction: We have made a lot of auto parts mould , and this auto wire bushing is made from soft rubber part, and by injection molding.

M old steel: S136

No. of cavities: 1*1

Part Material: soft rubber

Mold Base: LKM/HASCO/DME

Surface treatment: Texture/High Glossy/polishing

Runner: Hot runner/Cold runner

Shaping mode: Plastic Injection Molding

Mold lifetime: 100,000~1,000,000 shots

|

Trade Information

|

MOQ: 1 set

Mold lead time: 3~7 weeks for T1

Production lead time:2~5 weeks, according to order qty

Mold payment terms: 50% deposit by T/T against PO, balance by T/T after approval of samples but before shipment

Products payment terms: 30% deposit by T/T against PO, balance by T/T before shipment

Port of loading: Xiamen or other China port, as per customers' requirements

|

Product Image

|

|

Our Services

|

QQS Moulds provides services of plastic part design, prototype making, mold design, mold production, mass production in house. Moreover, we have reliable partner for painting, PCBA making and final assembly. We are working with many clients both home and abroad, and we keep every process very transparent with customers, because we hope to have a win-win situation for both parties.

|

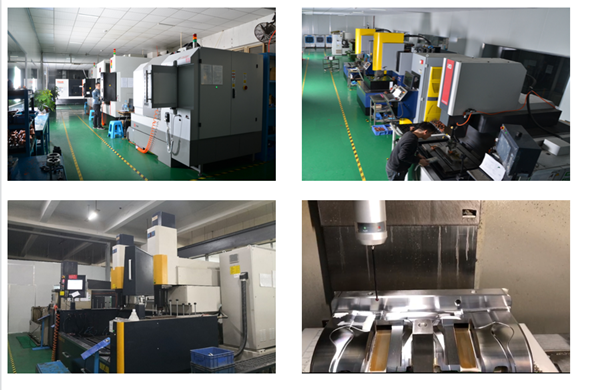

Our Equipment

|

|

Our Certificates

|

|

FAQs

|

Q: Do you make molds for many Auto Parts?

A: Yes, we make molds for many auto parts, such as bumper, reversing radar part, auto control panel, mirror support, etc.

Q: Do you have injection machine to produce the parts?

A: Yes, we have our own injection shop, so we can make the production & assembling for customers, if request.

Q: What kind of molds are you making?

A: We mainly make plastic injection molds, but we can also build compression molds (for UF or SMC material) & die casting molds.

Q: How long does it take to build a mold?

Q: Is it possible for us to know the schedule of molds without visiting your factory?

Q: How do you guarantee the quality?

Α: Θα διορίσουμε έναν διαχειριστή έργου για να ακολουθήσει τα καλούπια σας, ο οποίος είναι υπεύθυνος για κάθε διαδικασία. Εκτός από αυτό, έχουμε QC για κάθε διαδικασία, και θα έχουμε επίσης CMM & online σύστημα επιθεώρησης για να εγγυηθούμε ότι όλα τα εξαρτήματα είναι εντός των ορίων ανοχής.

Ε: Υποστηρίζετε OEM;

Ε: Με τι είδους ρητίνη προχωράτε;

Request for Quotation

Request for Quotation